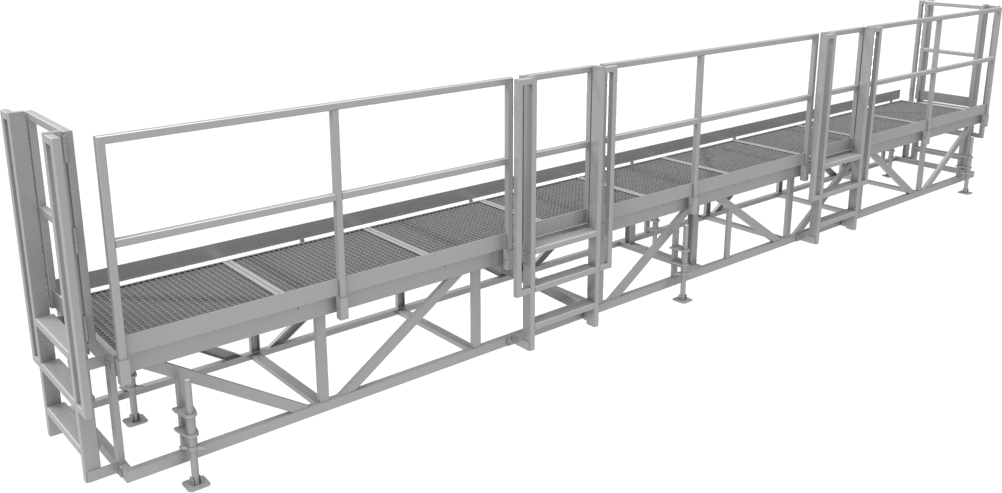

GRP handrail systems, assembled from special corrosion-resistant structural profiles are technically and economically good solution for corrosion-endangered areas.

The material advantages compared with galvanized steel is considerably.

Stainless steel systems are more expensive. Fiberglass polyester railing convince with a long life, lowest maintenance costs. Fast processing and simple assembly are further plus points.

Railing Construction:

Post (Square tube 50x50/5mm)

handrail (rounded U-Profile 60x70/5mm)

eknee pipe (tube 40x34mm)

Skirting board below (Profile 100x15/4mm)

Feets (GRP-post or V4A-feets) and fiberglass reinforcement / filler square bar

Handrail - and skirting board- connector ( horizontal, vertical or round)

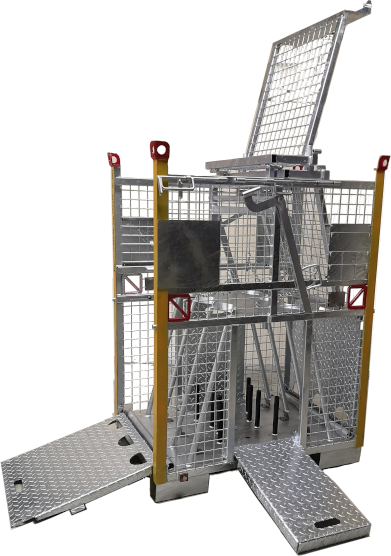

Assembly:

Cutting of the profiles is possible in the workshop and on the construction site. To mount the rail on a floor there are two variants available. One with stainless steel feet, or bolted with GRP Filler / square bar with 2 GRP knee pipe with the post and the ground together. Assembly of the railing sections to the posts is performed with pop rivets or with GRP Threaded Rods.