Carbon fibers are used instead of glass fibers as a reinforcement in the profiles for special applications. Epoxy resin as a matrix is mainly used.

The biggest difference in the properties of carbon fiber profiles (CFRP) compared to the fiberglass profiles (GRP) is the much higher stiffness (lengthwise).

The much higher price of the carbon-fiber–reinforced plastic limited the use for high-tech applications in the field of medical technology, robots, textile machinery, sports equipment, automobile and aircraft engineering etc.

The today used carbon fibers are primarily made from polyacrylonitrile (PAN) or regenerated cellulose (rayon). In a multistage process the pre-cursor will be firstly stabilized and then carbonized at about 1000 ° C.

The final temperature of this process determines the carbon fiber type:

> HT-fiber (high strength fiber) at 1200 ° C to 1450 ° C

> HM-fiber (high modulus fiber): up to 2500 ° C.

A layer, mainly based on epoxy, protects the fragile fibers from damage and facilitates subsequent processing. In addition to the great benefits of the very high (longitudinal) stiffness it must be noted that the C-fibers have differentmechanical strength properties vertical to the fiber axis, due to the structural design of the fiber.

Other physical properties like the thermal conductivity or the dilation are completely different.

In addition: the carbon fiber CFRP profiles or components are electrically conductive!

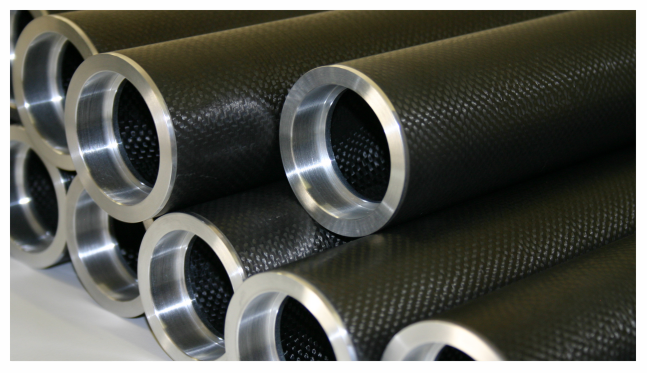

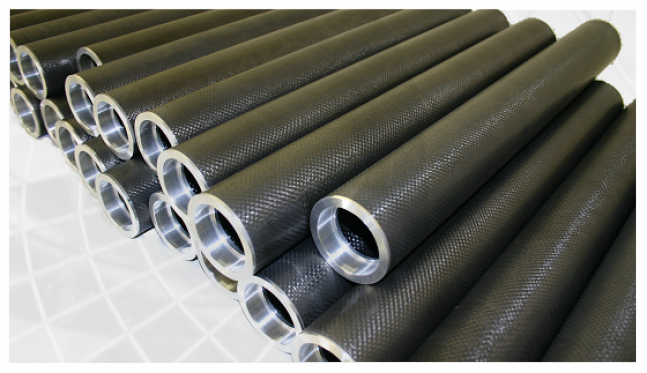

Apart from a limited standard range of (small) tubes, rods and plates are semi-finished products and components made from carbon fiber-epoxy usually available as taylor made products.

We manufacture profiles and components with the highest precision.

| Overview and Comparison of the material properties Subsequently, the mechanical properties of two carbon fiber-profile qualities compared with glass fiber-reinforced profiles: |

|||

| Quality> | Carbon-fiber-Epoxy | Carbon-fiber-Epoxy | Glass-fiber-Polyester |

| Unidirektional | 80%= / 20%+ / -6 | Rovings + Mat | |

| Properties: | (HT-Fiber) | (HMHT-Fiber) | (E-Glass) |

| Fiber content Gew.% | 68 | 68 | 60 |

| Density g/cm3 | 1,55 | 1,54 | 1,76 |

| tensile strength MPa | 1750 | 670 | 320 |

|

tensile strength E-Mod. GPa |

140 | 200 | 20 |

| Elongation % | 1,60 | 1,00 | 3,70 |

| Bending strength . MPa | 1550 | 320 | |

|

Bending strength E-Mod. GPa |

120 | 190 | 19 |

| This values are measured with standard specimens and compared with each other | |||